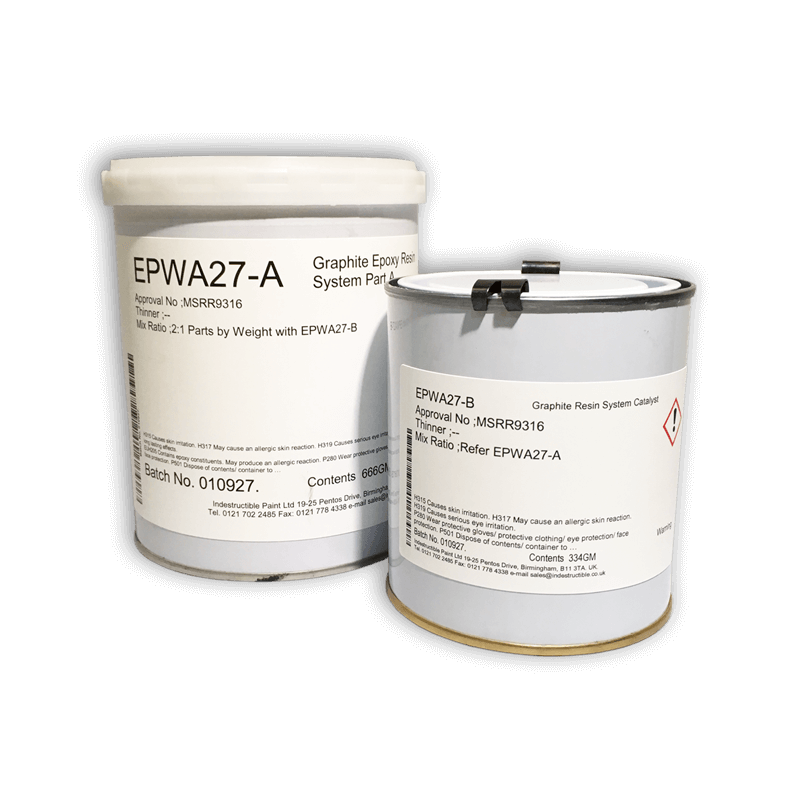

EPWA27 Abradable Attrition Coatings

Also known as PX/HX 443D. Graphite filled two part attrition compound which has almost totally replaced an earlier multi-coat spray system. Uses included the engine rings of the AB-8B Harrier. Hardness 72-75 Shore D-hardness, ASTM D2240. An alternative version is EPWA27 is available that was desigend to provide a 1:1 mix ratio. This product is not formally adopted but it represents and identical composition to EPWA27 when the two parts are mixed.

Description

Also known as PX/HX 443D. Graphite filled two part attrition compound which has almost totally replaced an earlier multi-coat spray system. Uses included the engine rings of the AB-8B Harrier. Hardness 72-75 Shore D-hardness, ASTM D2240. An alternative version is EPWA27 is available that was desigend to provide a 1:1 mix ratio. This product is not formally adopted but it represents and identical composition to EPWA27 when the two parts are mixed.Used in fan track linings where grooves are machined into the material; this is common in the compressor case area as ‘knife seals’ as it is denser then materials used in other areas. Processing of EPWA27 for Rolls Royce machinery is given in RPS 340/1. This data is evolved from the original use of the material on the Pegasus engine. The material will fully cure at room temperature; 90-95% cure is achieved after 24 hours at typical working temperatures; the final 5-10%of the cure will take place over the next few days. Provided that ambient temperatures are not too low; EPWA27 will be sufficiently cured after 24 hours to be fully resistant to solvents and cutting oils. EPWA27 is designed not to slump and thus allows faster application into thicker, deeper grooves.